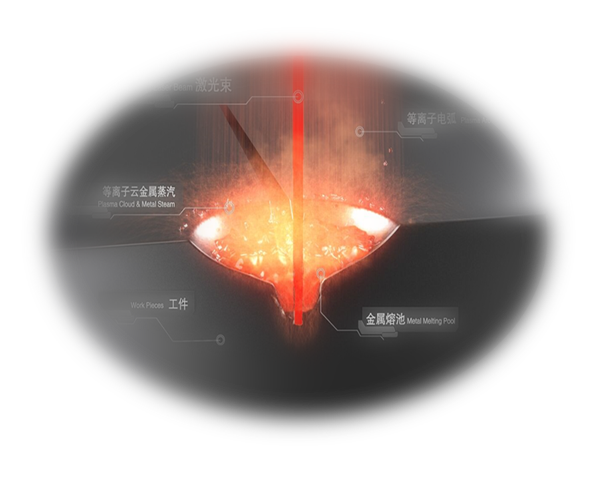

Jointly developed by industry elites in STR over many years, Laser-plasma hybrid welding technology is a welding technology possessing high energy density heat source. This technology superimposes laser on plasma co-axially to obtain a higher energy density heat source, which can be used for welding and cladding of various metals, as well as for laser cutting and surface treatment. It is suitable for manufacturing process in various industrial applications such as manufacturing new energy vehicles, steel body of household or commercial vehicles, high-speed rail and subway rolling stocks, white household electrical appliance, petrochemical equipment, ships, heat exchangers, and equipment used in aviation, space, defense, medical, sports, etc.

As a leading technology in the world, it has been certified that the welders adopting this technology can weld 6mm Series 7 aluminum plates and produce welded joints meeting Level I weld acceptance requirements.

Handheld Laser Welders

Handheld Laser Welders Special Welding

Special Welding Additive Manufacturing Series Fiber Lasers

Additive Manufacturing Series Fiber Lasers Narrow Linewidth Single Mode Fiber Laser

Narrow Linewidth Single Mode Fiber Laser High Power Single Mode Fiber Laser

High Power Single Mode Fiber Laser Core Components

Core Components Laser Welding

Laser Welding Additive Manufacturing (3D printing)

Additive Manufacturing (3D printing) Precision Processing Equipment

Precision Processing Equipment Marketing Information

Marketing Information Cooperative agents

Cooperative agents Product manuals

Product manuals News

News Join

Join Industry knowledge

Industry knowledge Company introduction

Company introduction Development history

Development history Technology&R&D

Technology&R&D Cooperative partner

Cooperative partner Corporate culture

Corporate culture Contact us

Contact us